Supply Technologies helps customers increase their competitive advantages by replacing costly, resource-intensive procedures with proven efficient Total Supply Management™ programs. Every one of the programs – whether it’s a Vendor Managed Inventory (VMI) program, one that’s integrated with your current system, or a tech support program – is expertly designed, implemented, and maintained to precisely address the customer’s unique needs. Each is customized per facility, flexible, scalable, and globally connected. And, because each is measurable in real time, we’re able to constantly evolve and improve programs to ensure optimum effectiveness.

Vendor Managed Inventory (VMI) programs help our customers significantly reduce manpower and resources, reduce inventory, and ensure ongoing quality - they are the ultimate in efficiency.

Programs are customized to exact distribution and floor specifications, and combine cross-industry best practices with the principals and techniques of Kanban, JIT, JIT II®, Vendor Managed Inventory (VMI), materials management, Lean manufacturing, Six Sigma and supply chain management to meet every need and requirement you have to optimize the production process.

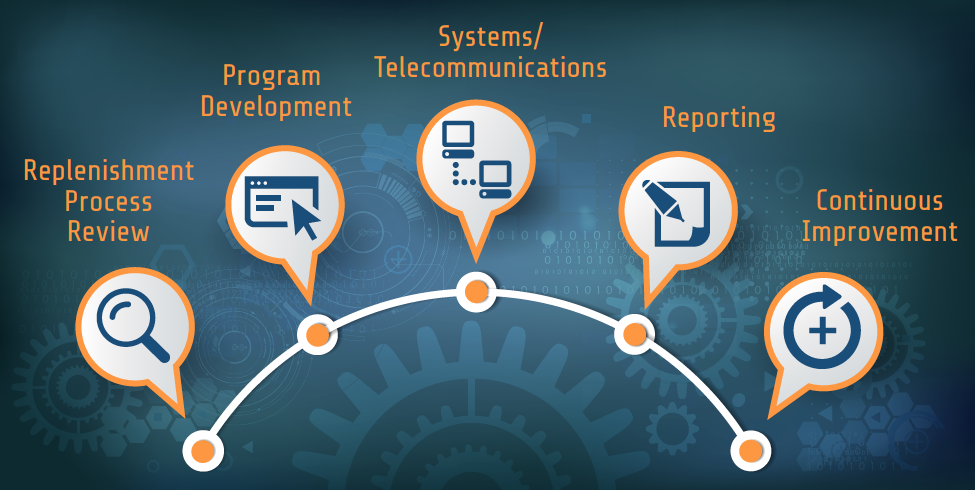

We first conduct an assessment of how your current process is performing, evaluating it critically to identify opportunities to save costs related to inventory, administrative time and/or space savings, and make optimal use of resources.

Using data collected during plant visits and floor audits, we develop a program with a cycle that optimizes inventory levels and movement of product through the plant, taking into account the processes that trigger replenishment, ranging from issuing purchase orders to scanning bar code labels at multi-bin inventory locations. Together, we'll all determine the best scenarios to optimize your manufacturing capabilities by delivering parts directly to central store, drop zones, or point of use.

Programs range from purchases via discrete purchase orders to full Vendor Managed Inventory (VMI), depending on requirements. The program design is complete from dock to stock and includes all touch points, including electronic replenishment, ASNs, staffing, inventory levels, container size, racking design, and eCommerce.

At the forefront of systems technology, our systems are fully integrated with our suppliers' and customers' backend systems.

Our time-phased planning system allows service level settings at the item level; settings include safety stock, buy times and lead times. Safety stock on items is automatically updated by the system based on recent demand and future forecast. The system allows for forward-looking forecast factors such as customer build rates – those forecasts are a critical part of our planning tools, and forecasts are transmitted to suppliers to ensure adequate lead times.

The system also manages inventory to avoid any surplus and obsolete inventory. The primary issue in managing surplus and obsolete inventory is to identify change in demand patterns on a timely basis.

We proactively ensure your program’s ongoing performance using risk management practices related to quality, purchasing, and packaging to accurately communicate the status of program components in a timely fashion. Reports include:

Supply Technologies works to earn your business every day by adding value to your organization and fulfilling our promise to be the supply chain efficiency experts. In both qualitative and quantitative ways, we openly communicate performance and actively listen to our customers’ ongoing needs.

Our internal sites for project management, document sharing, brainstorming and report delivery

We invest in "best in class" applications designed for one specific function fully integrated with our core transactional system

• Warehouse Management System

• Financial consolidation and forecast/planning

• Product planning

The ultimate cloud making it all possible for us to add value

Sharing information and collaborating with our suppliers and customers in real time

Custom applications designed to deliver information and content to any device

Transacting the full set of AIAG documents with both vendors and customers

Supply Technologies leverages some of the industry's most sophisticated technology intelligently deployed to support your business goals and objectives.

Every facet of every customer’s program – from program pre-planning to ongoing program support and enhancement – is brought together and made accessible 24/7/365 from any device, anywhere on a platform that:

Every aspect of your program and our own operations are integrated into a single ERP system that allows everyone – at every one of your locations across the globe – to understand what’s happening when and where, in real-time, via a sophisticated, easy-to-navigate dashboard. This leading-edge platform is designed for flexibility, transparency and interoperability with your own system, even if that system is a patchwork of legacy systems.

The platform is able to manage massive amounts of current inventory specifics and has the power to fully analyze past activities, anticipate future needs through various “what if” modeling scenarios, understand and plan replenishment cycles, seamlessly manage accounting functions, track productivity, and collaborate throughout the entire supply management process.

Our computing landscape extends the reach of our core backend application with a layer of increased functionality.

Supply Technologies and Total Supply Management are trademarks of Supply Technologies LLC.

All other trademarks are the properties of their respective companies.