Value Analysis & Engineering

- Home

- Solutions

- Continuous Improvement

- Value Analysis/Value Engineering

Value-Added Solutions That Improve Your Products

Supply Technologies’ Value Analysis/Value Engineering (VA/VE) solutions are thorough examinations of key product design elements that can significantly decrease your spend, reduce parts inventory, simplify manufacturing and assembly, and improve quality.

Through our experience across diverse industry sectors, we provide our customers with best practice recommendations, enabling you to optimize your designs with the latest and most cost-effective solutions. Benefits include:

- Part consolidation

- Product weight reduction

- Simplified assembly of components

- Reduction of similar products through standardization of design

- Improved product availability

- Lower total cost

Manufacturing Line Reviews

Our Customer Program Consultants and Sales Engineers use a team approach to perform Gemba walks to analyze material flow, understand how products are assembled, and make recommendations to increase productivity. Our experts assess current state and provide suggestions for improvements in the areas of efficiency, cost, quality, design and process.

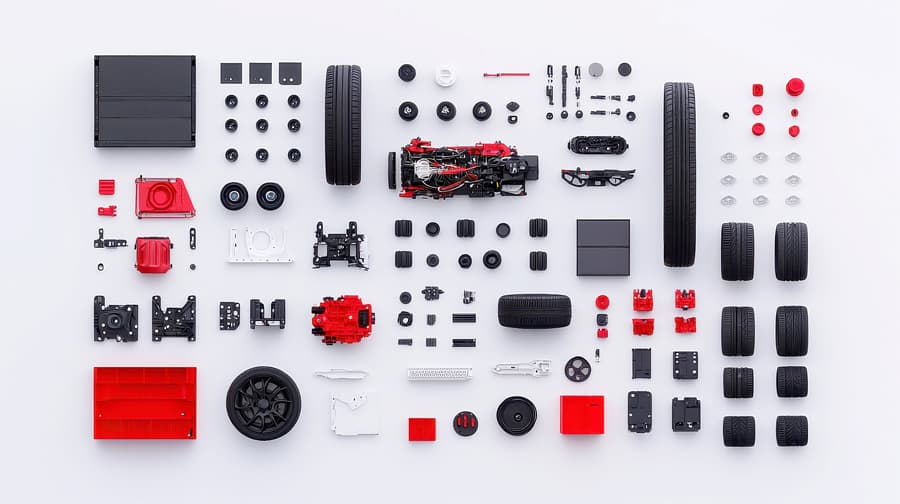

Product Teardowns

Our methodical approach to product teardowns identifies efficiencies, including how to:

- Reduce the number of parts in the assembly

- Decrease the cost of those parts

- Make assembly easier and faster

- Reduce weight

- Reduce warranty costs

This complimentary service also produces a detailed report that includes specific opportunities and cost estimations.

More Continuous Improvement Solutions

Supply Technologies uses robust data and insights to understand your unique needs. Leveraging 100+ years of experience working with our diverse customer base, our dedicated Business Intelligence & Analytics team delivers actionable insights to make strategic decisions related to your manufacturing processes.

Additional VA/VE Solutions

Part Consolidation & Product Standardization

Find opportunities to replace two or more assembly components with a single part, reducing the overall number of SKUs. We'll also help you eliminate multiple versions of a single part type in cases where standardization would reduce costs.

Product & Industry Training

Occasionally, your employees require training to familiarize themselves with new products or manufacturing processes. By providing these insights, we’re able to improve overall designs or provide solutions to existing problems.

Drawing & Specification Review

The best time to seek expert input about optimizing design and expected performance is when a product is in the design stage. We'll find ways to reduce part costs without reducing quality.

Our Products

Supply Technologies’ global sourcing with 7,000+ suppliers ensures you’ll get the exact parts you need, on time, at the highest quality and best value.

Contact Us Today

We've helped thousands of customers decrease their spend, reduce assembly component parts inventory, simplify manufacturing and assembly, and improve quality. Learn how we can help you improve your Total Cost of Ownership (TCO) with a custom solution.