Material Loop Management

- Home

- Solutions

- Total Supply Management

- Material Loop Magement

Experts in Supply Chain Continuity & Material Loop Management

We deliver supply chain reliability, so you'll always have the product you need, right when you need it. We take the pain and guesswork out of inventory by ensuring continuity of supply through a customized stocking strategy based on replenishment frequency, supply chain complexity, and forecast accuracy.

When you partner with Supply Technologies, we take on the responsibility of managing your supply chain. Our custom stocking solutions use proven methodologies to reduce inventory and free tied-up capital, yet still ensure inventory is on-hand when needed.

We offer the following to add value and ensure long-term success:

- Global sourcing network

- Access to 70+ global stocking warehouses

- Demand management accuracy measurements and forecast integration tools

- Tailored delivery and on-site management

- Point-of-use replenishment systems

- Analysis and reporting solutions

- BOM (Bill of Materials) validation and forecast accuracy insights

How We Ensure Guaranteed Inventory

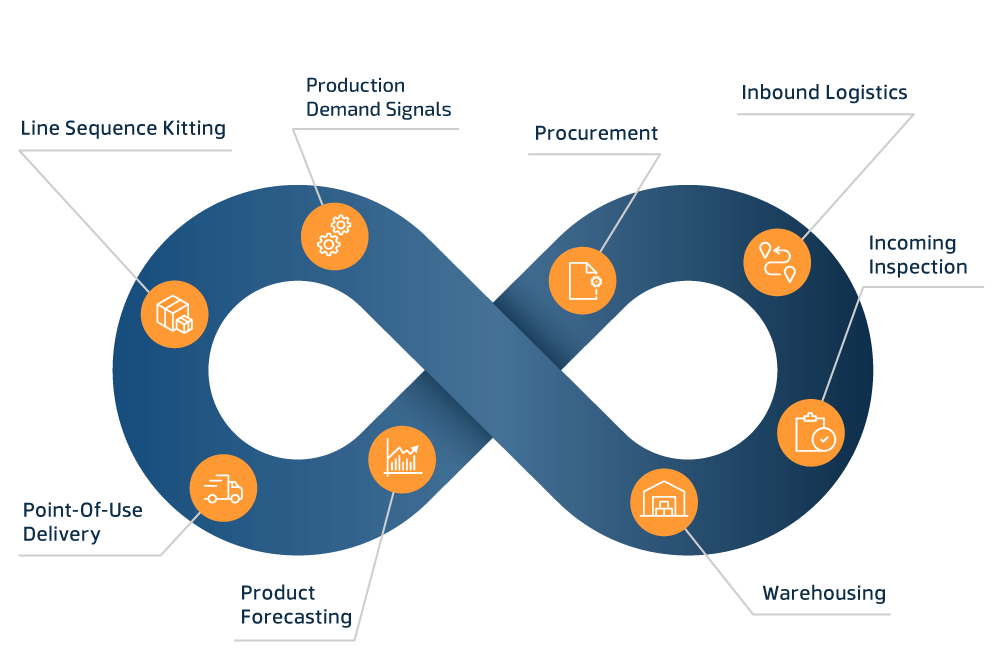

Our material loop management covers all aspects of the product life cycle as it pertains to your inventory:

We Offer These Innovative Solutions

Guaranteed Access to Inventory

Using a mix of on-site, local branch, and distribution center inventory storage, we ensure you always have reliable access to inventory where and when you need it. You can rest assured that the loop meets your requirements for an optimized stocking plan that drives down costs.

BOM Accuracy

We help you validate and cleanse your BOM, allowing you to improve your forecasts, reduce waste, and ensure cost accuracy for your final assembled products.

Planning & Forecasting Processes

Our advanced forecasting process measures historical sales and customer forecasts, performing days of inventory on hand (DOH) and a gap analysis to provide real-time updates and ensure continuity of supply.

Supply Technologies Portal

This online resource gives you full visibility and includes a series of analytics and reporting tools to provide valuable insights.

Tailored Delivery

We’re an agile partner that can customize delivery to meet your unique needs, from preparation and execution to nuanced fulfillment and replenishment options like line-side delivery.

Fulfillment

We provide scalable teams and resources based on your needs. Our teams take the stress and burden of managing onsite material off your plate so you can focus on more important tasks. We use technology to augment our fulfillment solutions to provide you with the data and insights you need to run your business.

How Our Material Loop Management Benefits You

Our material loop management solutions provide you confidence of supply continuity and help lower your working capital and operating expenses. By partnering with Supply Technologies, you reduce the costs associated with purchasing administration, receiving, material handling, quality assurance, and freight.

We design custom solutions to meet your material loop management needs, resulting in several benefits for your business:

- Improved stock availability

- Less inventory on hand/improved cash flow

- Reduced resources needed to manage procurement and sourcing

- Visibility into material flow and usage

- Reduction in process complexity and transactions

- Supplier consolidation and supply chain reliability

- Reduced complexity, so you can focus on other areas of your business

More Total Supply ManagementTM Solutions

Learn about our additional solutions that help improve efficiency, ensure components are available as needed, reduce inventory levels, optimize space, and improve cash flow.

Our Products

Supply Technologies’ global sourcing with 7,000+ suppliers ensures you’ll get the exact parts you need, on time, at the highest quality and best value.

Contact Us Today

We've helped thousands of customers find the simple solution for their most complex, high-volume assembly parts. Learn how we can help you produce better products more efficiently and cost-effectively.