Product Teardowns

- Home

- Solutions

- Continuous Improvement

- Value Analysis/Value Engineering

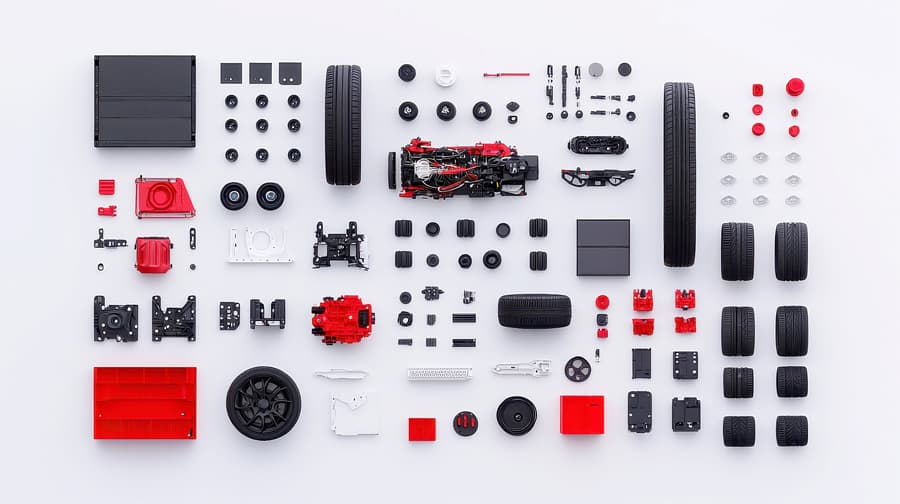

- Product Teardown

How We Help You Improve Product Design & Assembly

Supply Technologies' product teardown process focuses on identifying opportunities for cost and assembly improvements. As part of this service, you'll receive a detailed report with specific opportunities and estimated cost savings. Potential areas of improvement include:

- Part number reduction & standardization

- Weight reduction

- Cost & time reductions

- Joint design optimization

- Warranty claims reduction

Reduce Cost & Increase Efficiency

Our product teardown solution can be performed at your facility, our technical centers, or virtually using 3D CAD software. The seven-step process includes:

- Information gathering

- Disassembly

- Idea brainstorming

- Individual part standardization

- Part consolidation

- Idea cost estimation and ranking

- Report generation

Ongoing Process, Continuous Support

As one component of our Value Analysis/Value Engineering solutions, teardowns are routinely performed looking for further opportunities to leverage our cross-industry experience.

In addition to product teardowns, we perform Gemba Walks to analyze material flow, understand how products are being used and assembled, and make recommendations to increase productivity and reduce costs.

Our Products

Supply Technologies’ global sourcing with 7,000+ suppliers ensures you’ll get the exact parts you need, on time, at the highest quality and best value.

Contact Us Today

We've helped thousands of customers increase efficiencies and find simple solutions for their most complex high-volume assembly parts. Learn how we can help you improve your Total Cost of Ownership (TCO) with a custom solution.